As seen in a previous article dedicated to Kaizen, structured approaches enable better progress and a thorough analysis of what happens within a company. Today, we discuss two different schools of thought.

Origins of Quality Control

Quality control is frequently discussed, yet the origins of this fundamental process for any respectable company are often overlooked. Now more than ever, in an increasingly competitive world, adopting a structured approach is crucial.

In 1910, Ford decided to employ an inspector to analyze its products from a qualitative perspective. This marks the first instance of quality being discussed in this sense. Over the years, we evolved towards quality control in the 1930s, where products were sampled to verify their characteristics. In the 1980s, the concept of Total Quality Management (TQM) emerged.

TQM: What Is It?

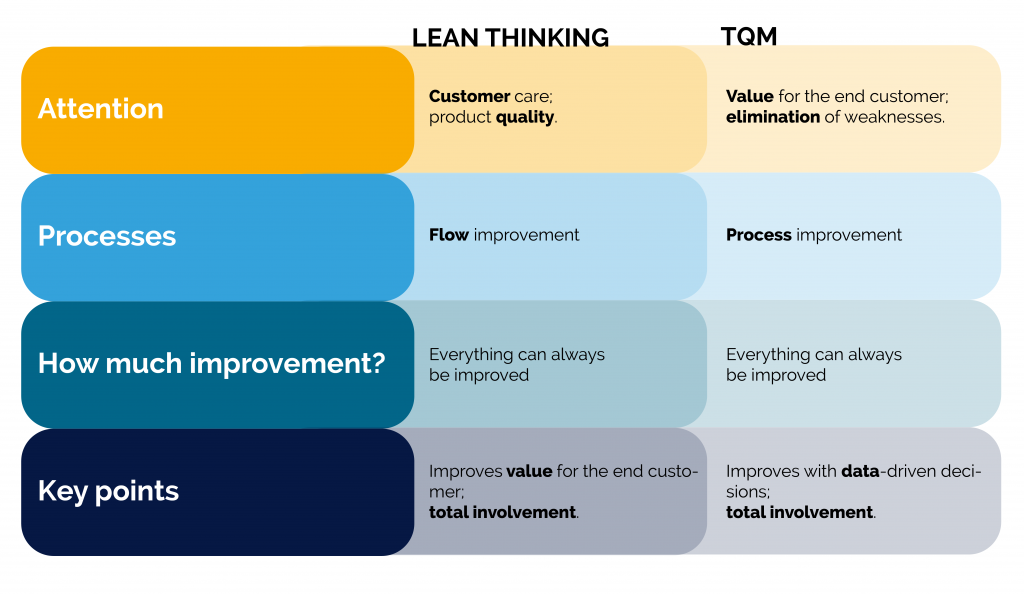

The acronym stands for Total Quality Management, indicating a well-defined management approach. The central focus is the constant monitoring of customer satisfaction, which cannot be separated from high quality. Essentially, this way of thinking is based on the continuous refinement of internal production methods to elevate what is offered externally to unprecedented levels.

TQM: 8 Key Concepts

- Data-driven decisions

- Communication

- Use of integrated systems

- Continuous improvement

- Total customer focus

- Utilization of the entire workforce

- Process-oriented approach

- Application of strategy

Advantages of TQM

This approach is highly effective in increasing customer satisfaction and the quality of the company’s production because it does not solely focus on the product. It may seem counterintuitive, but the product is just the tip of the iceberg. Before reaching this stage, one must consider everything underneath. It involves a lengthy and sometimes “painful” analysis, as it may require restructuring processes that were taken for granted.

First and foremost, internal communication, even before external, must be at the center of everything if real improvement is sought. Too often, poorly conceived services or products emerge simply because departments do not communicate.

Lean Thinking: What Is It?

This approach could be considered almost diametrically opposed to the first. Lean Thinking is primarily based on the total pursuit of value for the customer. How can everything we have be focused on satisfying the customer? Simply put, it requires cutting out all the superfluous. In this perspective, Lean Thinking analyzes all company processes in search of points that waste resources and, consequently, harm the end customer.

In Lean Thinking, the focus is more on the flows between processes rather than on individual processes.

Differences

Leave A Comment